itzz

Optimal choice for your victory

"itzz" is the brand with the largest share in the various kinds of races in the Japanese domestic, offering supreme quality brake solution to every single drivers in a wide range of the motor race.

R1

For slalom with an emphasis on control

For those who have trouble with ABS intervention or who don't want to lock the rear of the vehicle in FF

For those who have trouble with ABS intervention or who don't want to lock the rear of the vehicle in FF

FEATURES

| Applications | Rear of FF car Slalom Front |

|---|---|

| Ave Friction *1 | 0.22~0.26 |

| Temp Range | NT~400℃ |

| Material | Non Steel |

- Products targeted at slalom competition vehicles such as compact cars, FRs and MRs.

- Good compatibility with radial tires, and consideration was given to matching with brake assist and ABS

- Not only does it reduce the effect, but it also produces the effect according to the stepping force

- It is suitable for lightened FF cars and those who have trouble with rear lock

R2

Standard for rear-wheel-drive slalom, material with emphasis on controllability on low-micron roads

FEATURES

| Applications | Rear of FF car Slalom Front |

|---|---|

| Ave Friction *1 | 0.24~0.28 |

| Temp Range | NT~450℃ |

| Material | Non Steel |

- Standard for pylon gymkhana on FR and MR cars

- Excellent control performance in dirt trials on low-micron roads

- The initial response is stronger than R1

R3

For slalom with an emphasis on initial response

FEATURES

| Applications | Rear of FF Car Slalom Front |

|---|---|

| Ave Friction *1 | 0.26~0.30 |

| Temp Range | NT~480℃ |

| Material | Low Steel |

- Products mainly targeted at slalom competitions for FF cars

- The initial response is stronger than R2

- It can be used with FR and MR cars of high-speed course Gymkhana

R4

Standard for high power 4WD slalom

FEATURES

| Applications | Slalom Front |

|---|---|

| Ave Friction *1 | 0.28~0.32 |

| Temp Range | NT~500℃ |

| Material | Non Steel |

- Ideal for slalom competitions with high power 4WD vehicles

- The flat torque characteristic of non-steel material is characteristic, and the control is excellent

- Stronger in the back than in R3

R5

For slalom 4WD and light-weight rally vehicles with emphasis on effectiveness

FEATURES

| Applications | Emphasis on Slalom Effect Rally Front |

|---|---|

| Ave Friction *1 | 0.30~0.34 |

| Temp Range | NT~600℃ |

| Material | Non Steel |

- Highest heat resistance for slalom

- Emphasis on high temperature control performance

- Suitable for rallying lightweight vehicles

- It is also suitable for high speed gymkhana course with high power 4WD

R6

Standard for lightweight to medium-weight tarmac rallies

FEATURES

| Applications | Slalom Rear Rally Front/Rear |

|---|---|

| Ave Friction *1 | 0.32~0.35 |

| Temp Range | 100~600℃ |

| Material | Low Steel |

- Excellent initial response and emphasis on control at the back

- For light to medium-weight tarmac rallies and gravel rallies for medium-weight vehicles

- Superior to R5 in initial response and overall potency

R7

Ideal for medium-weight gravel rally vehicles

FEATURES

| Applications | Slalom Rear Rally Front/Rear |

|---|---|

| Ave Friction *1 | 0.34~0.37 |

| Temp Range | 100~600℃ |

| Material | Low Steel |

- For 4WD gravel rally vehicles with a master back

- Suitable for tarmac rallies of lightweight vehicles

- It has a better initial response and heat resistance than the R6, and can be used for the rear pad to get a better balance at the rear

R8

A heavyweight gravel rally car, a masterless modified dirtola

FEATURES

| Applications | Rally Front |

|---|---|

| Ave Friction *1 | 0.36~0.40 |

| Temp Range | 100~650℃ |

| Material | Low Steel |

- Initial response is milder than R7, but heat resistance is better

- For rallies with long SS for light to medium-weight vehicles

- For long SS 4WD vehicles with Masterbuck, with emphasis on controllability

R9

Ideal for 4WD tarmac rallies!

FEATURES

| Applications | Slalom Rear Rally Front/Rear |

|---|---|

| Ave Friction *1 | 0.39~0.43 |

| Temp Range | 100~700℃ |

| Material | High Steel |

- For tarmac rallies with long SS for lightweight and intermediate vehicles

- Tarmac rally standard 4WD rally vehicle with a master back

- Excellent heat resistance and braking power from high speed due to the high steel material

R10

Ideal for 4WD tarmac rallies!

FEATURES

| Applications | Rally Front |

|---|---|

| Ave Friction *1 | 0.42~0.45 |

| Temp Range | 100~800℃ |

| Material | High Steel |

- There is a long SS 4WD car with a master back for tarmac rally

- High temperature efficacy is more important than low temperature efficacy

- Heat resistance for long SS

R11

Products for Master Backless Vehicles

FEATURES

| Applications | Rally Front |

|---|---|

| Ave Friction *1 | 0.45~0.53 |

| Temp Range | 300~850℃ |

| Material | High Steel |

- Products for Master Backless Vehicles

- High initial response and efficacy from low to high temperature

- Heat resistance for long SS

Appendix

- *1 The results are based on our original dynamo test codes that simulate slalom and rally competitions. Therefore, it is not possible to compare the coefficient of friction with the ARMA series.

- The coefficient of friction cannot be compared with the coefficient of friction of other manufacturers due to the different Dynamo test conditions.

RM1

Slalom competition only, Rear full metal pad

FEATURES

| Applications | Slalom Rear |

|---|---|

| Ave Friction *1 | 0.53~0.55 |

| Temp Range | NT~300℃ |

| Material | Full Metal |

- Standard rear full metal pad for slalom competitions

- A product that balances the effectiveness of the foot and side brakes

- The pad may stick to the rotor after a long period of parking because it is only for the competition

RM2

Rear full metal pad for slalom competition with side lock performance

FEATURES

| Applications | Slalom Rear |

|---|---|

| Ave Friction *1 | 0.55~0.60 |

| Temp Range | NT~300℃ |

| Material | Full Metal |

- The rear metal pad for slalom competitions with the highest priority on side lock performance

- More effective than the RM1, with excellent response when the side brake is pulled

- The pad may stick to the rotor after a long period of parking because it is only for the competition

RM3

Rear full metal pad for rally

FEATURES

| Applications | Slalom Rear |

|---|---|

| Ave Friction *1 | 0.48~0.53 |

| Temp Range | NT~500℃ |

| Material | Full Metal |

- This is a metal pad for the rear of a rally

- Emphasizes heat resistance to prevent degradation of effectiveness even at high temperatures

- Side lock performance is inferior to RM1

- The pad may stick to the rotor after a long period of parking because it is only for the competition

Appendix

- *1 The RM series and RS series values are based on the rear test codes, so it is not possible to compare the coefficient of friction with the R1 to R11 series.

- The results are based on our original dynamo test codes that simulate slalom and rally competitions. Therefore, it is not possible to compare the coefficient of friction with the ARMA series.

- The coefficient of friction cannot be compared with the coefficient of friction of other manufacturers due to the different Dynamo test conditions.

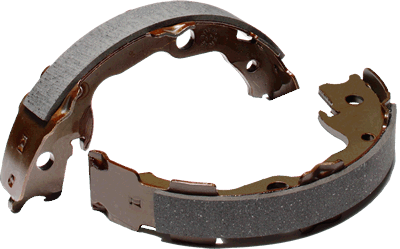

RS1

High performance brake shoe for rear drum brakes

FEATURES

| Applications | Highway Shoe |

|---|---|

| Ave Friction *1 | 0.30~0.35 |

| Temp Range | NT~300℃ |

| Material | Non Steel |

- For vehicles with rear drum brakes

- 20% more effective than the stock shoe

RS2

Competition parking shoe with side locking performance

FEATURES

| Applications | Inner shoe for side turn |

|---|---|

| Ave Friction *1 | 0.40~0.50 |

| Temp Range | NT~350℃ |

| Material | Non Steel |

- Specially developed for vehicles with parking shoes

- It locks the rear with an overwhelmingly high intensity

- Because it is only for the competition, if the clearance is too much, dragging will occur ※Please follow the instruction manual carefully when installing the product.

Appendix

- *1 The RM series and RS series values are based on the rear test codes, so it is not possible to compare the coefficient of friction with the R1 to R11 series.

- The results are based on our original dynamo test codes that simulate slalom and rally competitions. Therefore, it is not possible to compare the coefficient of friction with the ARMA series.

- The coefficient of friction cannot be compared with the coefficient of friction of other manufacturers due to the different Dynamo test conditions.