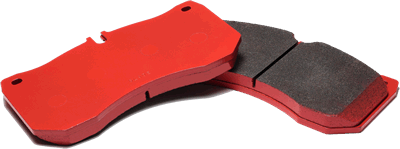

ARMA CIRCUIT

Brake pads for time attacks and sprint races on full circuits

(Only available in Japan)

The ARMA Circuit Series are the brake pads for full-circuit events, time attacks and sprint races.

The material was designed in consideration of vehicle speed, deceleration, brake fluid pressure, and rotor temperature during full-circuit driving in order to endure use on the harsh full-circuit.

AC1

The most control-focused model

FEATURES

| Ave Friction *1 | 0.37~0.40 |

|---|---|

| Temp Range | 50~650℃ |

| Material | Mid Steel |

- It has the most control of the four types

- Especially for full circuit driving of light to medium weight cars

- Linear effect on stepping force

- As the rear of FF cars that want to prevent the rear lock

AC2

A standard model with a good balance of power and control

FEATURES

| Ave Friction *1 | 0.39~0.43 |

|---|---|

| Temp Range | 100~750℃ |

| Material | High Steel |

- All-purpose full-circuit brake pads for any track or car type

- There is a moderate initial bite, and the deceleration performance and controllability from high speed range are balanced in a high dimension

- If you're wondering what to do on a full circuit, this model is the one to start with!

AC3

A model that combines potency performance and durability

FEATURES

| Ave Friction *1 | 0.45~0.48 |

|---|---|

| Temp Range | 300~800℃ |

| Material | High Steel |

- Superior pad life and high efficacy

- For full circuit braking

- No rapid build-up and great control

AC4

Model with the highest priority on efficacy performance

FEATURES

| Ave Friction *1 | 0.47~0.52 |

|---|---|

| Temp Range | 300~850℃ |

| Material | High Steel |

- Initial byte, set the overall potency as high as possible

- As a time attack and race pad for heavy and high power cars

- For master backless vehicles

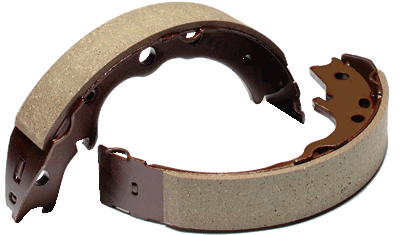

ACS

Rear shoe to match the front AC series

FEATURES

| Ave Friction *1 | 0.35~0.38 |

|---|---|

| Temp Range | NT~400℃ |

| Material | Non Steel |

- Improved rear lock prevention and fade resistance for rear of FF cars.

Appendix

- *1 The coefficient of friction is the result of our original dynamo test and cannot be compared with the coefficient of friction of other manufacturers' products.

- The friction coefficients of the ARMA CIRCUIT series are the result of dynamo test codes that assume circuit driving.